Patterned liquid crystal (LC) optics can be used to change properties of light, like the phase or polarization state, on micron scales. Moreover, these LC optics can be used to modify the phase or polarization state with extremely high efficiencies over large spectral bandwidths. This is especially useful as the phase that LC optics generate is a different type of phase called geometric phase. Geometric phase is, unlike phase delays from glass optics, independent of wavelength. This means that LC optics modify light the same way for the full spectral bandwidth, which is crucial for many applications in high-contrast imaging like exoplanet characterization. The combination of high efficiency and full control of achromatic phase or polarization state over large bandwidths is unmatched by other technologies like glass etching, photolithography, or metamaterials.

The LEOPARD group uses patterned LC optics for high-performance coronagraphs and highly efficient wavefront sensors, polarimeters, aperture masks, and masks for exoplanet astrometry or photometry. The LEOPARD group works together in close relation with ImagineOptix, a company that develops and manufactures the LC optics.

People: Frans Snik, David Doelman, Steven Bos, Christoph Keller, Matthew Kenworthy.

Pictures of two liquid crystal optics taken with a microscope. Both demonstrate highly complex patterning enabled by liquid crystal technology.

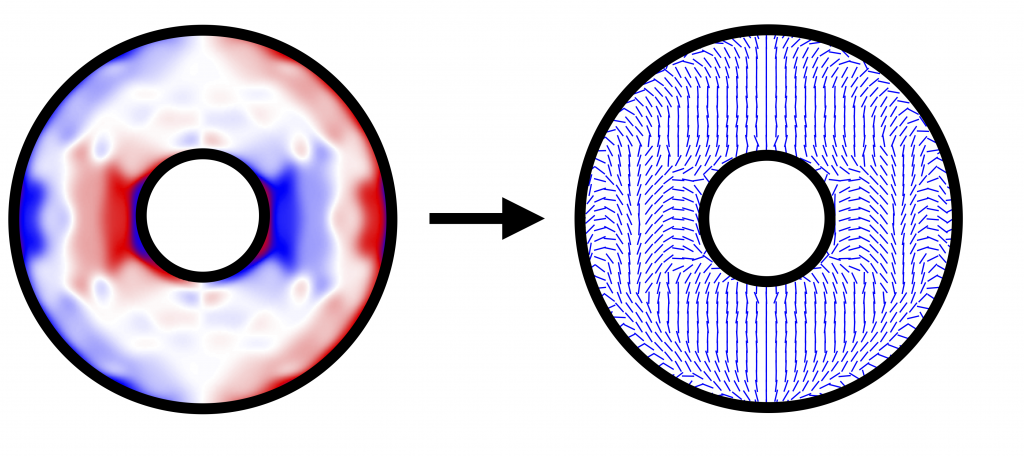

By changing the phase of light, it is possible to reshape the point-spread function (PSF), the way the light is spread around the star in a telescopic image. The PSF can be manipulated to exhibit properties that are advantageous for high-contrast imaging. For example, it is possible to create a region where starlight is suppressed to a degree where exoplanets become visible. Moreover, it is possible to add light in regions to help with sensing optical aberrations in the imaging system, or to have precise reference copies of the stellar PSF to find temporal variability of the exoplanet signal.

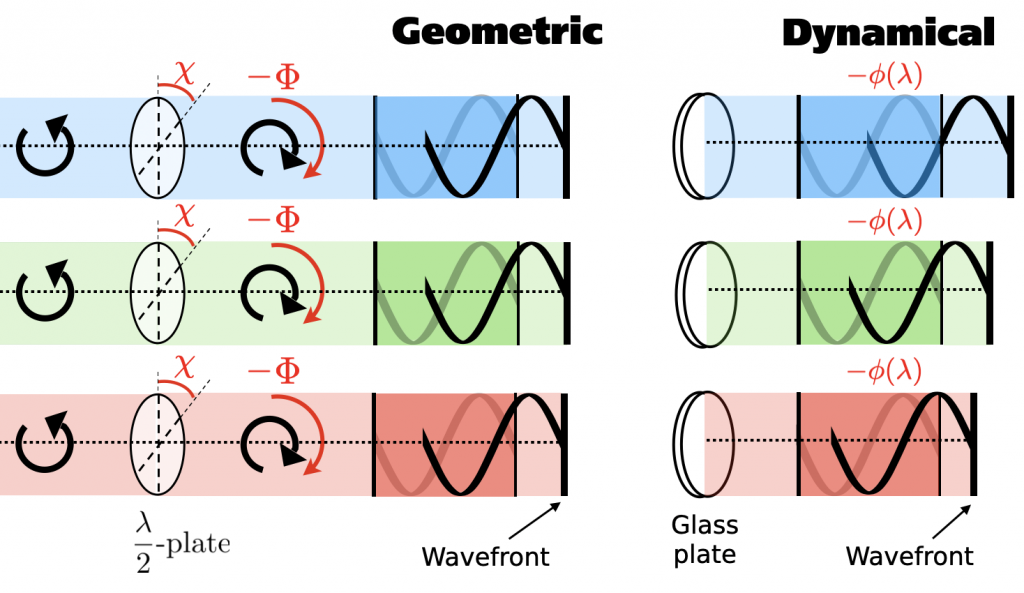

Modifying the PSF for these applications requires precise control of the phase on micron scales. Changes in the phase reduce the performance. Therefore, a change in the phase as function of wavelength, like the dynamical phase from glass optics, are a major limitation for broadband optics. This change in of phase as function of wavelength is visualised in the image below. By using liquid-crystal optics that apply wavelength independent (geometric) phase, this problem is solved.

Comparison between geometric phase and dynamical phase. The different colors indicate the wavelength. A geometric phase shift is induced for light going through a rotated half-wave retarder, as indicated by the shifted waves. This shift is independent of wavelength. A phase shift generated by a glass plate does depend on wavelength.

Let’s look shortly at the details of the functioning of the liquid-crystal optics and the geometric phase, which is different from dynamical phase. Dynamical phase arises from differences in optical path length, like a glass plate with varying thickness. Instead, geometric phase arises when circularly polarized light propagates through a retarder with a locally changing fast-axis orientation. The circular arrows in the figure above indicate the circular polarization state. The geometric phase then only depends on this local geometry of the fast-axis and the handedness of the circularly polarized light, and is therefore independent of wavelength. The fraction of light that acquires the geometric phase, the efficiency, depends on the retardance and is 100% for a half-wave retarder. The fraction of light that does not acquire geometric phase is called polarization leakage.

The phase pattern of liquid-crystal optics is encoded in an orientation pattern of the fast-axis. Different orientations of the fast-axis induce a different geometric phase. Their position does not change with wavelength, so the phase is achromatic.

ImagineOptix is a pioneer in manufacturing liquid crystal optics with high efficiencies over large spectral bandwidths and control of the fast-axis orientation, and thus the induced geometric phase on micron scales. ImagineOptix uses a direct-write system to imprint patterns in a LC alignment layer by scanning the surface with a UV laser. This alignment layer orients itself differently depending on the linear polarization state of the UV laser, which is accurately controlled to within a degree. Additional birefringent LC layers are deposited on top of the alignment layer to control the retardance. By tuning the thickness and twist of these layers, efficiencies over 96% can be realized over an octave of spectral bandwidths. Together with the LEOPARD group multiple broadband LC recipes have been developed between 0.5-5 micron.s

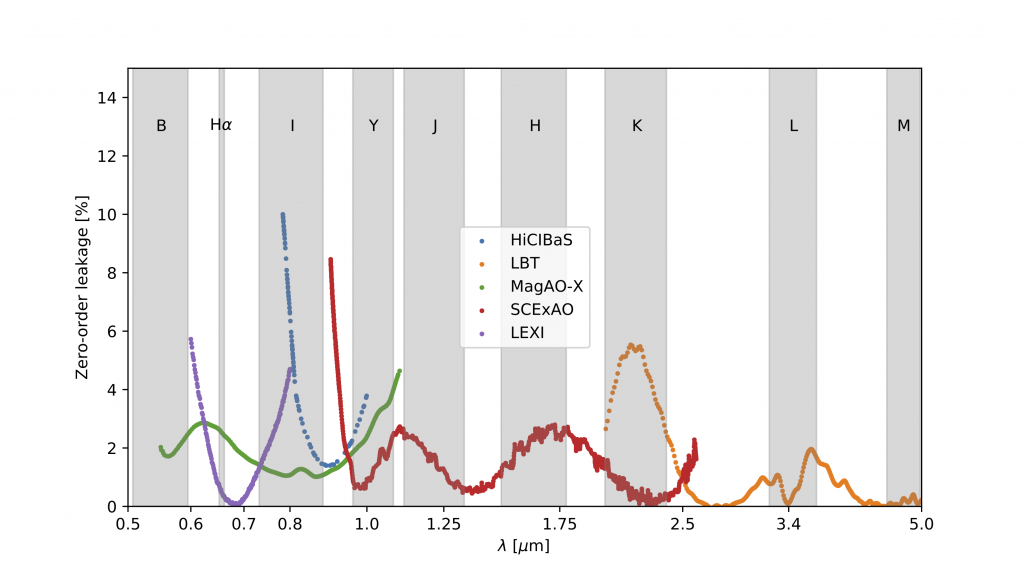

ImagineOptix is capable of producing liquid-crystal layers that have low polarization leakage over large spectral bandwidths. A lower leakage increases the performance of coronagraphs. The colors indicate the leakage for different instruments where a vAPP coronagraph is installed.

The properties of liquid crystal optics provide unique opportunities for high-contrast imaging systems (HCI). The LEOPARD group takes advantage of these opportunities to develop new concepts that improve HCI systems on a system level, with the ultimate goal to detect life on exoplanets.